Waste Management

Sewage Pump - PSS Series

Have Question?

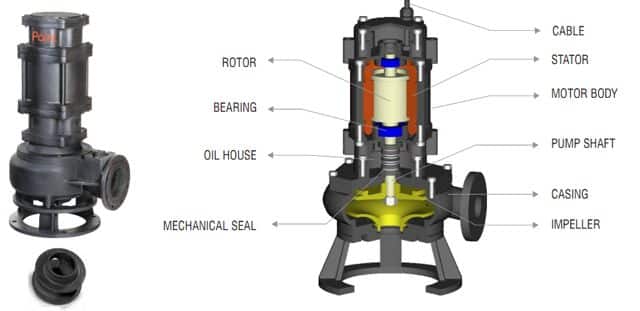

- About Product

- Cross Sectional View

- Dimesional Drawing & details

- Performance Curve & Table

These pumps are designed for pumping sewage, sludge containing a very large proportion of solid or fibrous material. These pumps comes with enclosed two channel impeller with replaceable wear ring and large spherical clearance. For special applications, impellers and volutes are available in graded steels.

| Model | A | B | D | H |

| 100PSS-80-6-4.0 | 250 | 186 | 100 | 570 |

| 100PSS-80-7-5.0 | 250 | 186 | 100 | 660 |

| 100PSS-80-9-6.0 | 250 | 186 | 100 | 660 |

| 100PSS-80-10-7.5 | 292 | 194 | 100 | 740 |

| 100PSS-80-12-7.5 | 292 | 194 | 100 | 740 |

| 150PSS – 160 – 7 – 7.5 | 286 | 227 | 150 | 765 |

| 150PSS – 160 – 8 – 7.5 | 286 | 227 | 150 | 765 |

| 150PSS – 160 – 9 – 10 | 286 | 227 | 150 | 765 |

| 150PSS – 160 – 11 – 10 | 286 | 227 | 150 | 765 |

| 150PSS – 160 – 13 – 15 | 286 | 227 | 150 | 1005 |

| 150PSS – 160 – 15 – 15 | 286 | 227 | 150 | 1005 |

| 200PSS – 300 – 20 – 40 | 440 | 343 | 200 | 1810 |

| 200PSS – 300 – 25 – 50 | 440 | 343 | 200 | 1810 |

| 250PSS – 500 – 10 – 40 | 477 | 362 | 250 | 1925 |

| 250PSS – 500 – 14 – 50 | 477 | 362 | 250 | 1925 |

| 300PSS – 700 – 10 – 40 | 437 | 411 | 300 | 1680 |

| 300PSS – 700 – 12 – 50 | 437 | 411 | 300 | 1680 |

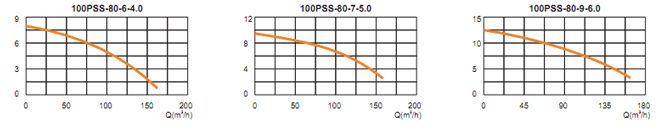

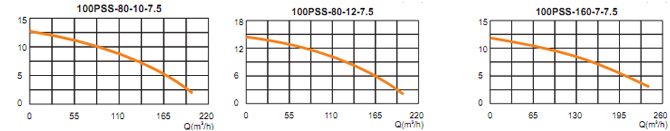

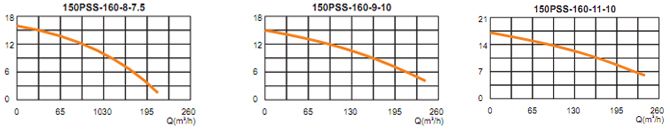

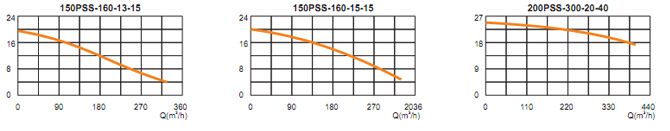

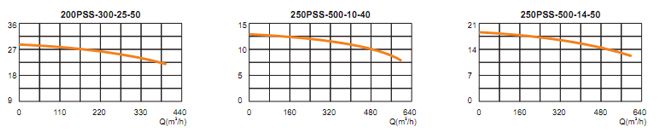

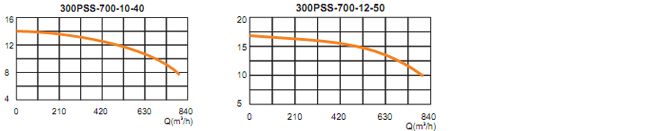

Performance Curve

Performance Table

| S.No | Model | Motor Power HP/ kW | Particle | Q(m3/h) | 40 | 80 | 120 | 160 | 200 | Â | Â | Â |

| 1* | 100PSS – 80 – 6 – 4.0 | 4.0 / 3.0 | 90 | Head (m) | 7 | 6 | 4 | – | – | – | – | – |

| 2* | 100PSS – 80 – 7 – 5.0 | 5.0 / 3.7 | 90 | 9 | 7.5 | 5.5 | 2.5 | – | – | – | – | |

| 3* | 100PSS – 80 – 9 – 6.0 | 6.0 / 4.5 | 90 | 11 | 9 | 7 | 3.5 | – | – | – | – | |

| 4* | 100PSS – 80 – 10 – 7.5 | 7.5 /5.5 | 90 | 11.5 | 10 | 8 | 5.5 | 2 | – | – | – | |

| 5* | 100PSS – 80 – 12 – 7.5 | 7.5 /5.5 | 90 | 135 | 12 | 10 | 37 | 42 | – | – | – |

| S.No | Model | Motor Power HP/ kW | Particle | Q(m3/h) | 80 | 160 | 240 | 320 | 400 | Â | Â | Â |

| 6* | 150PSS – 160 – 7 – 7.5 | 7.5 / 5.5 | 135 | Head (m) | 10 | 7 | 3 | – | – | – | – | – |

| 7* | 150PSS – 160 – 8 – 7.5 | 7.5 / 5.5 | 135 | 11.5 | 8 | 3.5 | – | – | – | – | – | |

| 8* | 150PSS – 160 – 9 – 10 | 10 / 7.5 | 135 | 13 | 9 | 4 | – | – | – | – | – | |

| 9* | 150PSS – 160 – 11 – 10 | 10 / 7.5 | 135 | 15 | 11 | 6 | – | – | – | – | – | |

| 10* | 150PSS – 160 – 13 – 15 | 15 / 11 | 135 | 17 | 13 | 8.5 | 4 | – | – | – | – | |

| 11* | 150PSS – 160 – 15 – 15 | 15/ 11 | 135 | 18 | 15 | 10.5 | 5 | – | – | – | – | |

| 12* | 200PSS – 300 – 20 – 40 | 40 / 30 | 180 | 24 | 23 | 21.5 | 20 | 17.5 | – | – | – | |

| 13* | 200PSS – 300 – 25 – 50 | 50 / 37 | 180 | 28 | 27 | 26 | 24.5 | 22 | – | – | – |

| S.No | Model | Motor Power HP/ kW | Particle | Q(m3/h) | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 |

| 14* | 250PSS – 500 – 10 – 40 | 40 / 30 | 225 | Head (m) | 12.5 | 12 | 11.5 | 11 | 10 | 8 | – | – |

| 15* | 250PSS – 500 – 14 – 50 | 50 / 37 | 225 | 18.5 | 18 | 17 | 15.5 | 14 | 12 | – | – | |

| 16* | 300PSS – 700 – 10 – 40 | 40 / 30 | 270 | 14 | 13.8 | 13.5 | 13 | 12.2 | 11.2 | 10 | 9 | |

| 17* | 300PSS – 700 – 12 – 50 | 50 / 37 | 270 | 16.7 | 16.5 | 16.2 | 15.8 | 15.2 | 14 | 12 | 10 |

Contact us

Get in touch for enquiries and offers.